Marketing Areas

- HOME

- Marketing Areas

- Wire Galvanizing

Production Plant

Wire Galvanizing

Production Plant

- 01

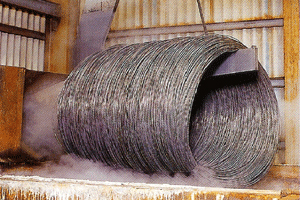

Wire Rod

- 02

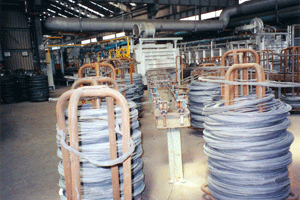

Pickling

- 03

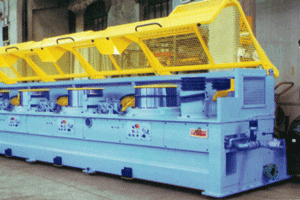

Drawing Machine

- 04

- 05

- 06

- 07

- 08

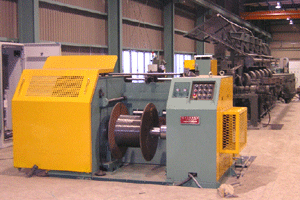

Strander Machinery

- 09

Products

Wire Rod

Pickling

After removing rusts of scales on the surface of a wire rod with chemical medicines, the surface of a wire is coated with lubricants; it is equipment that makes the 2nd process easier.

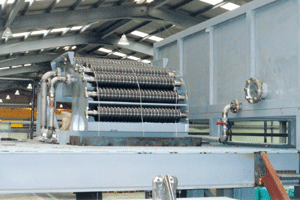

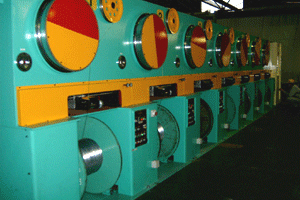

Drawing Machine

• Over head type

• Continuous straight line

- Dancer arm type

- Back pull type

- Sensing arm type

• Diameter of capstan : Φ200 ~ Φ900

- This machine has accurate performance and easy operation by using inverter motor control.

- The high speed drawing can be achieved by high cooling effect by means of complete wetting of the inside wall of the drums.

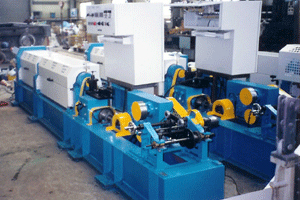

Pay-off Equipment

• Effective delivery of wire to the process quipment is essential if maximum plant

efficiency is to be maintained to be maintained to meet individual customer

• Pay-off frames supplied by protect are developed and manufactured

- Wire tension strength be controlled by inverter motor

- High speed operation

- Bobbin supply

- Carrier supply

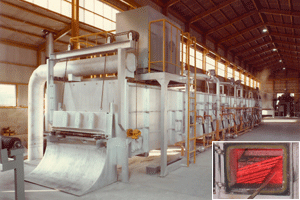

Patenting Furnace

• Usage : Heat treatment (patenting, annealing, tempering etc.) for various steel wire

• Type : Compulsion convection type

• Character

- Cost efficiency & heating

- Reduction of the heating time

- Reduction of scale generating amounts

- Even distribution of the temperature in the furnace

- Easy to control atmosphere by inputting the protecting gas

- Reduce the temperature of wasted gas

Lead Furnace

- Long life of bath structure

- Low deflection of temperature distribution by automatic temperature control system

- Air cooling for bath interior and outside

- Lead circulation pumping device

- Sand box device for lead wiping

- Simple structure for lead temperature by auto combustion device

- Auto temperature controller and safety equipment

- Partition for prevention of wire tangle on entrance and exit side

Water Quenching Bath

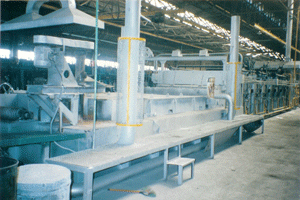

Fumless Pickling

- Hcl or H2SO4 can be used

- Fabricated in FRP or Polypropylene

- Cost effective acid management

- Automatic acid temperature control up to 60℃

- Change acid without stopping production

- Internal air wipe system

- Partition for prevention of wire tangle

- Water curtain on Inlet & Exit side

- The circulation of pickling in bath

Water Rinsing Bath

Flux Bath

Dryer

Galvanizing Furnace-Class 5

- Galvanizing furnace in order to protect the erosion of steel wire, spring washers, small parts, bolt & nuts and etc.

- The structure is divided with a ceramic parts and a heating cover.

- The furnace is parts appropriately used in all kinds of a heating system.

- You can select fuels such as kerosene, light oils, heavy oils, gas and electricity.

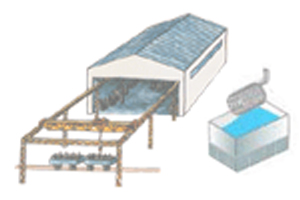

Cooling System

Cooling Bath

Cooling Tower

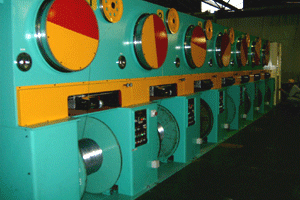

Take-up Equipment

- Horizontal type & Vertical type

- Spool type & Coiler type

- Manufactured by bobbin flange Dia. from 300 to 1800mm and by consumer's characteristic and specification

- Accuracy of each parts and durability

- Easy speed control of separated by electricity control system each group

- Straightening device for wire cast and prevention of wire surface defect

Galvanizing Furnace-Class 1

Take-up Equipment

- Horizontal type & Vertical type

- Spool type & Coiler type

- Manufactured by bobbin flange Dia. from 300 to 1800mm and by consumer's characteristic and specification

- Accuracy of each parts and durability

- Easy speed control of separated by electricity control system each group

- Straightening device for wire cast and prevention of wire surface defect

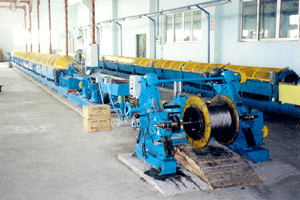

Strander Machinery

- Tubular strander & closer of bobbin flange diameter from 100mm to 1000mm as well special types in comply with customer's intention.

- Supporting stands with encircling antifriction bearings or on heavy fully-sized under rollers.

- Centralized lubricating system for bearing.

- Pneumatic & Hydraulic disk brake.

- Cradle bobbin set with shaft of shaftless type

- Wire tension be controlled by slip brake or lectronic brake

Products